PREREQUISITE STUDY:

This web page summarizes the advantages of FNRs over water cooled reactors for civilian land based electric and thermal power generation. It is presumed that the student is already familiar with the general design of water cooled power reactors and has already studied the web pages titled: FNR CONCEPT and FNR DESCRIPTION.

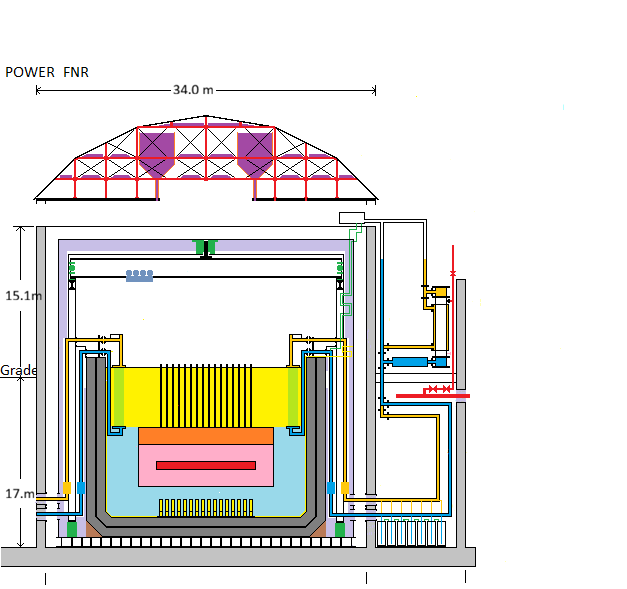

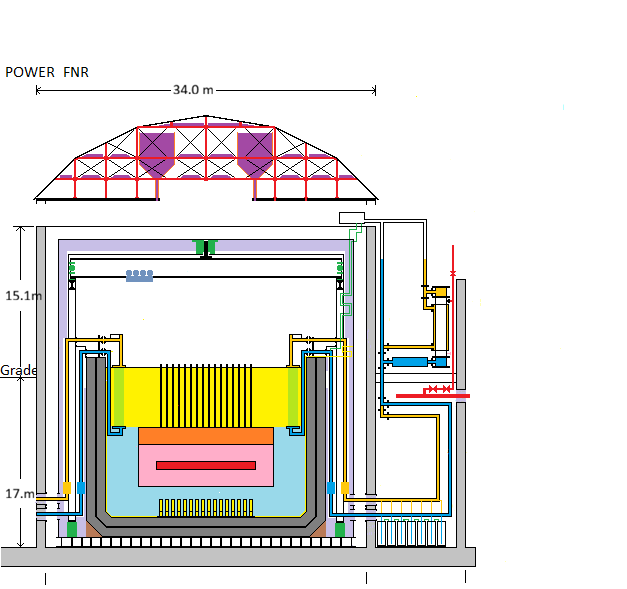

FAST NEUTRON REACTOR SIDE ELEVATION:

The profile diagram of a FNR is provided below to remind the student of the general configuration of a FNR.

For clarity in the above diagram the fuel bundle support steel lattice and the air locks are not shown.

Only 1 of 48 heat transfer loops is fully detailed.

Color Code:

Red - Reactor Core, Steam Main

Pink - Reactor Blanket

Orange- Fuel Tube Plenum

Gold- Warmer NaK pipe

Yellow- hot sodium, hydraulic sodium tube, hydraulic lifter

Light Green - Intermediate Heat Exchange tubes

Dark Green - Hot wall thermal brake support, polar gantry bearings,

Light Purple - Fiber Ceramic Insulation

Dark Purple - NaCl Reservoir

Light Blue- cool sodium

Dark Blue - Cooler NaK Pipe

Light Gray - Concrete

Dark Gray - Fire Brick

Black - Steel Outline

OVERVIEW:

In 2020 most existing nuclear power reactors are water moderated. The term "water moderated" means that the core of the reactor contains water which absorbs most of the kinetic energy from energetic neutrons emitted during the fission process before these neutrons are reabsorbed by the fuel. Water moderated power reactors have a relatively high power density, were initially developed for military submarine applications and are primarily fuelled by the relatively rare uranium isotope U-235.

Water moderation of nuclear reactors water has several distinct disadvantages for civilian electricity and power generation including: high fluid operating pressure, essential continuous mechanical core coolant pumping, potential void related power instabilities, wasteful use of natural uranium, large scale production of long lived nuclear waste and more frequent reactor shutdowns for refuelling.

In many land based electricity and thermal power production applications, where the lower reactor power density of a FNR is of little consequence, the chemical, physical and nuclear properties of sodium provide many advantages over water.

ADVANTAGES OF LIQUID SODIUM COOLED FNRs:

1. The liquid sodium cooled Fast Neutron Reactor (FNR) described herein avoids the disadvantages of a water moderated reactor by using naturally circulated liquid sodium rather than pumped water for reactor core heat removal, by using fast neutrons rather than slow neutrons for fissioning transuranic atoms, by using a neutron absorbing blanket for converting fertile fuel atoms into fissile fuel atoms and by using a sodium guard band to prevent fast neutron damage and neutron activation of non-fuel reactor components.

2. With suitable fuel recycling this liquid sodium cooled FNR can provide up to 100 fold more energy per kg of mined natural uranium than can a CANDU reactor. The nuclear properties of sodium allow design of reactors that produce more fissile fuel atoms than they consume;

3. With suitable fuel recycling FNRs can reduce net production of long lived nuclear waste by more than 1000 fold. The nuclear properties of sodium allow design of reactors that allow transmutation of long lived high atomic weight elements, such as those contained in used CANDU fuel, into short lived low atomic weight elements, as required for nuclear waste disposal. A FNR disposes of nuclear fuel waste generated by other reactor types by fast neutron fissioning of the waste transuranic atoms.

4. A distinct advantage of FNRs is that they are almost unaffected by slow neutron poisons. This feature allows a FNR to be easily power modulated from 8% to 100% of its plate rating by changing its secondary NaK flow rate. Hence, unlike CANDU reactors, the thermal output power of a FNR can follow a rapidly changing grid electricity load arising from rapid variations in the uncontrolled output of grid connected intermittent renewable energy generation. Note that although the system thermal output power can be rapidly changed the rate of change of power in the FNR fuel assembly is limited by the large thermal mass of the liquid sodium pool.

5. The primary liquid sodium coolant in a FNR operates at a low pressure rather than a high pressure, which simplifies many reactor design, construction, operation, maintenance and safety issues.

6. Since the FNR Na and NaK coolants operate at a low pressure there is no requirement for a public safety exclusion radius.

7. Unlike a water cooled reactor in a FNR there is nothing radioactive that can potentially blow up. The FNR radio isotope containment system never has to deal with either high pressures or hydrogen production. This feature is key to enabling safe urban siting of FNRs.

8. Apart from the fuel assembly nothing is subject to either neutron activation or fast neutron related material degradation. Almost all the nuclear power plant components are modular and replaceable, potentially enabling a facility service life of many centuries rather than just 60 years as with a CANDU reactor.

9. If the reactor enters a prompt neutron critical state some of the sodium inside the fuel tubes immediately boils forcing rapid core fuel disassembly by fuel rods being propelled into the fuel tube plenum. This rapid fuel disassembly prevents a reactor blowup.

10. The reactor reactivity decreases with increasing temperature providing reliable over temperature chain reaction shutdown.

11. Unlike water, sodium does not have potential void instabilities in its operating temperature range. The core fuel is normally about 9 m deep in the primary liquid sodium pool. The corresponding primary liquid sodium pressure head raises the sodium coolant boiling point temperature to about 980 degrees C. The liquid sodium pool must enormously over heat before the sodium vapor pressure in the Na pool is sufficient to form a void.

12. Unlike water cooled reactors there is no source of hydrogen within the FNR pool space. Any high pressure steam and/or hydrogen produced in the electricity generation portion of a FNR based nuclear power plant is outside the muclear island and can be safely vented to the atmosphere.

13. A major advantage of liquid sodium as a reactor coolant is its chemical compatibility with steel. In a practical FNR that operated for 30 years there was no detectable corrosion of the sodium pool walls that were fabricated from stainless steel. A sodium guard band is used to protect the stainless steel pool walls from neutron impingement.

14. The physical properties of sodium are such that no physical damage is caused by sodium freezing within steel pressure pipes.

15. An important feature of new FNRs is passive safety. On loss of electrical power the system defaults to a safe cool shutdown condition without human intervention.

16. The overall safety advantages of low pressure liquid sodium cooled fast neutron power reactors allow them to be sited in the middle of an urban area and autonomously operated. If there is any problem, including loss of station power, the reactor defaults to a safe shutdown state with certain fisson product decay heat removal.

17. A FNR with a gadolinium skirt plus a 1.8 m wide sodium guard band around the fuel assembly and recycled fuel and Na produces no decommissioning waste;

18. At full load a FNR with natural primary sodium circulation provides heat to its steam generator in the temperature range 450 deg C to 330 deg C as compared to 320 deg C to 280 deg C for CANDU reactors. The higher FNR working temperature improves the heat to electricity conversion efficiency and reduces the required heat sink capacity, which reduces the impact of the nuclear power plant on the environment.

19. The higher primary coolant temperature allows efficient electricity generation with evaporative cooling rather than direct lake water cooling;

20. Due to the reduced requirement for cooling water a FNR can be sited much further above the local water table and surrounding bodies of water than a direct water cooled reactor, thus enhancing system safety in rare but severe events such as floods, earthquakes, hurricanes, meteorite strikes, tsunamis, etc.

21. A FNR has normal passive high temperature chain reaction shutdown due to solid fissile fuel thermal expansion. If the fissile fuel temperature exceeds the fuel melting point the liquid fuel will flow downwards inside the fuel tube displacing liquid sodium between the blanket fuel rods and the fuel tube inner wall. The consequent decrease in fissle atom concentration will shut down the nuclear reaction;

22. A FNR has two independent mechanical cool shutdown systems each of which will independently respond to an equipment fault;

23. A FNR has a passive cold shutdown mode to which it defaults on loss of station power. In cold shutdown natural circulation of secondary NaK and evaporation of stored water remove fission product decay heat;

24. The passive safe shutdown features are critical for safe FNR siting within major cities;

25. The FNR is contained within an enclosure which reliably excludes air and water from the primary sodium pool;

26. A FNR has redundant natural draft dry cooling towers for certain rejection of fission product decay heat by dry cooling when station power is available. On loss of station power cooling is by steam rejection;

27. A FNR has a high output power ramp rate and turbine steam bypass so that it can dump thermal energy on sudden loss of grid load;

28. A FNR features include rapid on-site assembly from factory built and tested truck transportable modules;

29. Warehoused modules provide delivery schedule certainty and, if necessary, rapid repair via module replacement;

30. FNR fuel bundles typically have 15X the working life of water cooled reactor fuel bundles;

31. FNR shutdowns for refueling are infrequent. Typically 20% of the fuel bundles are changed once every six years. During the refuelling process some of the irradiated active fuel bundles are moved from their operating positions to their fission product decay cooling positions while remaining immersed in primary liquid Na.

32. The FNR has up to 48 independent secondary heat transport circuits so that there is certainty relating to removal of decay heat by natural NaK circulation after fission reaction shutdown;

33. FNRs achieve a very high capacity factor because normally at any instant in time only a small fraction of the NPP capacity is shut down for maintenance.

34. FNRs breed fertile fuel into surplus fissile fuel to enable FNR

fleet expansion;

35. The argon cover gas over the FNR liquid sodium surface is always at atmospheric pressure which minimizes reactor enclosure structural forces.

36. The full load secondary NaK flow velocity within the intermediate heat exchange bundles is chosen to minimize heat exchange tube internal erosion while maintaining a sufficiently turbulent flow for good heat transfer.

37. The FNR intermediate heat exchange bundles, which are potentially subject to minor internal pressure stress and internal erosion, are not exposed to the neutron flux. Hence the service life of the intermediate heat exchange bundles is enhanced and when they do need replacing a simple exterior surface cleaning will remove all radio activity allowing economic repair and material recycling. Isolating the intermediate heat exchange bundles from the neutron flux enables use of a high performance nickel alloy (Inconel 600) in the intermediate heat exchange bundles without causing neutron activation of the nickel;

38. The steel components of a FNR fuel bundle assembly that are exposed to a high neutron flux are replaced and recycled at the same time as the reactor fuel. During normal FNR operation a small fraction of the iron in this steel is transmuted into chromium.

39. A major non-obvious advantage of FNRs is a nearly infinite fuel supply. Since a FNR consumes natural uranium at less than 1% of the consumption rate of a water moderated reactor a FNR can economically utilize natural uranium resouces that have very low uranium concentrations. That feature greatly increases the total available natural uranium resource.

40. The scientific issues related to FNRs have been well understood since the late 1960s. The practical metallurgy issues were resolved by about 1990. Today there is no valid reason for not deploying FNRs.

41.The FNR described herein will withstand horizontal earthquake accelerations of up to 1.26 g _____without physical damage. Earthquakes that produce horizontal accelerations of greater than 1.26 g _____are extremely rare. This relatively high earthquake tolerance is enabled by the relatively low density of liquid sodium as compared to other liquid metal and molten salt coolant alternatives. In an earthquake the pool contents tend to remain in position while the pool structure, which is attached to the ground, shakes. The resulting earthquake excited transverse forces on the pool structure, fuel bundles and intermediate heat exchangers increase with the coolant density.

COMMENT ON IMPORTANT FNR FEATURES:

In FNR core fuel the trans-uranium actinides preferentially fission, instead of simply capturing neutrons as in a water moderated reactor. With appropriate periodic fuel reprocessing a FNR yields about 100 fold more energy per kg of natural uranium than does a heavy water moderated CANDU reactor. During fuel reprocessing the fission products are extracted from the fuel. About 95% of the extracted fission products decay to safe levels within 300 years. Hence on a per kWh basis the rate of FNR long lived spent fuel waste production is about:

100 X 20 = 2000 fold

less than for a CANDU reactor.

The best method of spent CANDU fuel disposal is to reprocess the used CANDU fuel into new FNR fuel and then consume it by reducing it to fission products in a FNR.

In summary, in land based civilian nuclear electricity and thermal power generation liquid sodium cooled power FNRs can provide sufficient energy to sustainably displace fossil fuels with almost no net production of long lived nuclear waste. FNRs can also be used to safely dispose of spent fuel from CANDU and other water moderated nuclear reactors.

FNR DISADVANTAGES:

The major disadvantages of a liquid sodium cooled FNR are that the sodium chemically reacts violently on with water and that above 200 degrees C sodium spontaneously burns in air.

The chemical incompatibility of sodium and water makes liquid sodium cooled nuclear reactors unsuitable for marine applications or for use at any site that might in the future be subject to flooding by water.

As a consequence:

a) Liquid sodium cooled FNRs are inherently unsuitable for marine applications;

b) The liquid sodium pool of a FNR must be located above the highest possible future flood water level. This requirement makes FNRs unsuitable for siting on river flood plains or on the edge of large water bodies that might be subject to future earthquakes, tsunamis or sea level rise;

c) For fire safety the liquid sodium pool of a FNR requires a highly reliable gas tight enclosure to provide an argon gas cover. Each FNR should have a dual on-site cryogenic argon production facility;

d) For supplementary fire safety the primary liquid sodium pool of an FNR should have a steel cover comprised of floating steel spheres and an automatic NaCl based fire suppression system;

e) Due to the required separation from large water bodies FNRs usually reject surplus heat to the environment by air cooling or by evaporation of smaller amounts of water rather than by direct water cooling.

f) In urban district heating systems surplus heat resulting from electicity generation should be preferentially rejected via a multiplicity of remote natural draft cooling towers that operate dry in the winter and wet in the summer.

OTHER FNR ISSUES:

1) Local fire department personnel must be trained to NEVER use water to fight a fire in a liquid sodium cooled FNR facility. The FNR has a local 300 tonne supply of NaCl for primary sodium fire suppression. The system is designed to dump secondary NaK into argon covered below grade dump tanks. A preferred above grade extinguishing agent is Na2CO3.

2) A significant issue with liquid sodium is its relatively small heat transport capacity per unit volume as compared to water. In order to transport heat either the volume of the liquid sodium coolant has to be increased four fold as compared to water or the differential temperature across the heat transport loop has to be increased four fold.

Gemerally in order to minimize the pumping energy requirement the heat transport loop differential temperature is increased which causes significant thermal stress related design issues and imposes temperature contraints on the thermal load.

3) A significant security issue with FNRs is that they operate with a large Pu inventory. During FNR operation first-in first-out fuel bundle replacement should be followed to maintain a sufficient Pu-240 concentration in the fuel to prevent stolen FNR fuel ever being used for fabrication of fission bombs.

4) Since FNRs are not located near large bodies of water they require adjacent small (~ 8% of reactor capacity) natural draft dry cooling towers for reliable rejection of fission product decay heat. In normal operation the FNR heat output is absorbed by a district heating system. In an urban environment excess heat can be rejected by remote fan coil units and cooling towers distributed across a city.

5) The FNR described herein sacrifices power density to achieve some of its benefits. This reactor type is not intended for use in marine applications that have severe space and weight limits. These constraints are not a significant issues in most civilian electricity and thermal power generation applications.

ENGINEERING CONSIDERATIONS:

A disadvantage of cooling with liquid sodium as compared to water is the lower heat capacity of sodium.

A major issue with liquid sodium cooled FNRs is full automation of fuel bundle production and fuel reprocessing. The power FNR described herein has 510,944 fuel tubes in 1689 fuel tube bundles containing about 6,000,000 fuel rods. In order to make FNRs economic all aspects of FNR fuel rod, fuel tube and fuel bundle production and fuel recycling must be fully automated. This automation requires a major capital commitment.

SAFETY ADVANTAGES OF FNRs AS COMPARED TO WATER COOLED REACTORS:

Liquid sodium cooled FNRs inherently provide several major safety advantages as compared to water cooled reactors. At a pressure of one atmosphere water boils at 100 degrees C, a temperature far below the water cooled reactor maximum operating temperature of 320 degrees C. Sodium at a pressure of one atmosphere boils at 883 degrees C, a temperature far above the FNR maximum operating temperature of 520 degrees C. This difference in boiling point relative to reactor operating temperature has important implications.

1) If water is used as a reactor coolant any coolant leak will flash into radioactive steam. In an accident situation this radioactive steam cannot be safely vented to the atmosphere at an urban reactor site. Liquid sodium cooled FNRs avoid this problem by use of low pressure liquid sodium as the primary coolant. The primary liquid sodium is isolated from the turbo-generator working fluid steam by two separate series connected heat exchangers with low pressure working fluids. Thus there is no radiotoxicity hazard in venting turbo-generator steam to the atmosphere.

2) Water cooled reactors have a potentially dangerous condition known as transient void formation in which when the coolant pressure drops steam bubbles form in the reactor fuel tubes. These steam bubbles reduce the heat transfer capacity and reduce the reactor reactivity. To compensate for the reduced reactor reactivity the water cooled reactor power control system will automatically withdraw control rods to maintain the desired power setpoint. Then if the cooling feedwater temperature suddenly drops or the cooling water pressure is restored the steam voids can rapidly collapse leading to a reactor explosion due to prompt neutron criticality. The causes of void formation include coolant circulation failure or coolant pressure drop due to a pipe rupture, a pump failure or a loss of pump power. By contrast the contemplated FNRs rely on natural circulation of low pressure primary liquid sodium which has a boiling point about 480 degrees C above the normal maximum liquid sodium operating temperature. The nuclear chain reaction shuts down on high temperature. Hence in a liquid sodium cooled FNR there is no issue of transient void formation. If there is a local high temperature hot spot caused by prompt neutron criticality the FNR core fuel disassembles by blowing part of the fuel toward the fuel tube plenum.

3) Water cooled reactors rely on ongoing mechanical movement of control rods to control the reactor power. This control methodology has many possible failure modes. This control system must constantly operate because water cooled reactors are inherently unstable. Absent operation of the mechanical control system the reactor power would spontaneously rise or fall. By contrast in a FNR thermal expansion and contraction of the fuel assembly provides stable passive primary liquid sodium temperature control.

4)The FNR fuel choice and geometry is such that void formation in the primary liquid sodium injects positive reactivity but causes a fuel temperature rise which injects sufficient negative reactivity to stop the nuclear chain reaction. If the fuel temperature continues to rise due to prompt neutron criticality the increase in sodium vapor pressure inside the fuel tube causes fuel disassembly which will stop the nuclear chain reaction.

5) During severe accident conditions water cooled reactors vent radioactive gases to the atmosphere. By contrast in FNRs the only radioactive gases present remain sealed inside the steel fuel tubes.

6) Most existing water cooled power reactors rely on mechanical pumps for primary coolant circulation. In such reactors a primary coolant pipe break or loss of primary coolant pumping are constant and potentially dangerous threats. By contrast the FNR design contemplated herein uses multiple highly reliable natural circulation loops for both sodium and NaK circulation. The only significant essential pumping is nitrate salt/oil circulation sufficient for fission product decay heat rejection.

7) Most existing water cooled power reactors rely on use of concrete casks for on-site dry storage of spent fuel bundles. By contrast after six years of in-sodium cooling on removal from the reactor used fuel bundles from FNRs are placed in lead shipping containers and are transported by road truck/train to a central fuel recycling site.

8) Water cooled reactors generate large amounts of used fuel containing highly radiotoxic transuranium actinides (TRUs). By contrast FNRs eliminate transuranium actinides (TRUs) by fissioning them.

9) Existing water cooled reactors generate large amounts of service and decommissioniong waste. By contrast each FNR contemplated herein has a 3 m wide liquid sodium guard band which prevents production of service and decommissioning wastes. In the event of a fuel tube rupture the primary sodium filter system will collect almost all the released fuel and fission product material for reprocessing.

We need to further investigate the issue of capture and recovery of radio cesium from a leaking fuel tube.

10) Water cooled reactors rely on complex electro-mechanical control systems to keep the reactor fuel and fuel tube temperatures within design limits. By contrast in a FNR the fuel and fuel tube temperatures are constrained by the primary liquid sodium temperature. The FNR fuel tube heat flux is limited by the maximum secondary NaK flow rate.

11. One of the issues in FNR design is ensuring that no matter what adverse circumstances occur, in an emergency gravity will assist the movable fuel bundles in falling into a safe cold shutdown position. The FNR enclosure must be sufficiently robust that an enclosure collapse or a crane collapse sufficient to crush the matrix of fixed fuel bundles is not a credible accident.

This web page last updated April 20, 2023